Tube Laser Cutting

Our tube laser cutting services deliver high-speed, burr-free cuts on round, square, and rectangular tubing, supporting structural, mechanical, and aesthetic parts across a wide range of industries.

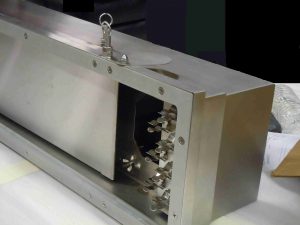

Precision Tube Cutting For Complex Builds

We use advanced tube laser systems to cut tight-tolerance profiles, slots, holes, and miters—reducing secondary operations and enabling clean weld-ready parts. Whether you need prototype brackets or full-frame assemblies, we cut with consistency, speed, and accuracy.

Various Tubing Profiles

We cut various tubing profiles including round, square, and rectangle in aluminum, steel, and stainless materials.

Clean Internal Cuts

Laser cutting delivers burr-free holes, slots, and notches—eliminating the need for internal deburring or rework.

Bevels & Miters

We produce angled cuts, miters, and custom bevels for easy alignment during welding or mechanical assembly.

Weld-Ready Edges

Parts are delivered with clean, tight edges—ready for immediate joining, fixturing, or downstream forming.

Batch & High-Volume Runs

Our setup supports fast processing for both short-run prototypes and full production assemblies.

Minimal Fixturing Required

Precision laser guidance allows complex cuts without extensive clamping, saving time and cost.

Built for Structure. Designed for Speed.

Whether you’re building machine frames, safety enclosures, or custom racks, our tube laser cutting services streamline your process. We reduce waste, cut setup time, and deliver components that are consistent, weldable, and reliable.

Markets We Power

Dimar’ Manufacturing Corporation s tube laser cutting capabilities support industries that demand strength, weldability, and fast production. From medical carts to power systems and packaging machines, our parts are used wherever clean tubing and precision connections matter.

Packaging

Laser-cut tubing for conveyor frames, machine skeletons, and material handling subassemblies.

Medical

Tubular frames, bases, and structures for carts, diagnostic systems, and lab support equipment.

Construction

Laser-cut tube parts for job site structures, railing, and pre-fabricated construction components.

Industrial

Structural supports, brackets, and frame components for OEMs and heavy-duty equipment builders.

Transportation

Durable, clean-cut tubing for transit systems, vehicle brackets, and infrastructure support parts.

Aerospace

Precision-cut tubular frames and brackets for ground test equipment and aerospace structural builds.

Energy

Frames, mounts, and racking systems used in battery storage, grid enclosures, and solar supports.

Agriculture

Structural tube assemblies for livestock enclosures, grain systems, and automated feeding lines.

Frequently Asked Questions

We answer the top questions about tube sizes, internal cuts, supplied material, and integration with forming or welding.

What tube sizes can you cut?

We cut round, square, and rectangular tubing in various sizes and wall thicknesses, contact us for specs.

Can you laser cut holes or slots in tubes?

Yes. We specialize in cutting complex features like holes, notches, tabs, and miters in tube profiles.

Do you offer tube forming or bending?

We focus on cutting services, but work alongside forming and welding operations for full assemblies.

Can you process customer-supplied tubing?

Yes, we can work with customer-provided material if it meets our quality and sizing standards.

Explore Our Tube Laser Projects

Our tube laser cutting department supports a wide range of structural applications, combining clean geometry with fast throughput. From kiosks to packaging frames, our tubing cuts are weld-ready and precise.

Start Your Tube Laser Cutting Project

Send us your part drawings or production specs, and we’ll deliver a fast, accurate quote. Dimar’s precision tube laser services are engineered for speed, quality, and reliability, every cut, every time.

Corporate Headquarters

10123 Main StreetClarence, NY 14031

Additional Location

4280 Research ParkwayClarence, NY 14031

Additional Location

40 Anderson RdBuffalo, NY 14225