CNC Machining

Our precision CNC machining services are trusted by manufacturers in industries like packaging, medical, energy, and industrial equipment to transform complex designs into high-tolerance, production-ready components.

Precision Machining, Powered by Experience

From one-off parts to full production runs, Dimar Manufacturing’s CNC machining cell offers speed, repeatability, and dimensional accuracy. Our milling and turning equipment handles complex geometries, tight tolerances, and critical finish requirements.

3-Axis Milling

We machine brackets, housings, and flat or prismatic parts with clean edges and consistent repeatability.

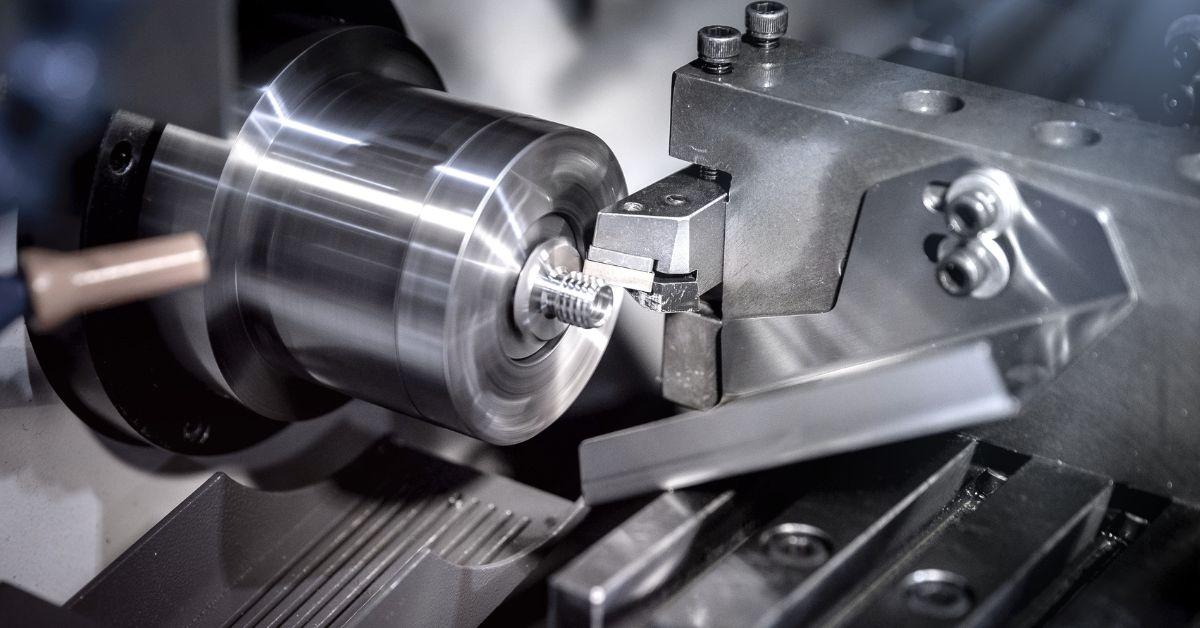

Turning & Lathe Work

Tight-tolerance turned parts, shafts, and bushings with concentricity and surface finish control.

Multi-Side Machining

We reduce setups and improve accuracy by machining multiple faces of a part in a single process.

High-Mix, Low Volume

Flexible programming and tooling allow us to machine small batches without sacrificing quality.

Precision Fixtures

Custom fixturing for tight-tolerance parts ensures part stability and reduced variation during production.

Material Versatility

We machine aluminum, stainless, carbon steel, plastics, copper, and brass with clean, consistent results.

Built for Control. Backed by Quality.

Our machining department is supported by in-house quality control, calibrated inspection equipment, and experienced setup personnel. We meet dimensional specs, surface finishes, and production deadlines, without compromise.

Markets We Power

Our CNC machining services are trusted by manufacturers across regulated and industrial sectors. From tight-tolerance aerospace parts to machined components for energy grids and packaging systems, our shop delivers consistency, speed, and finish quality.

Packaging

Machined parts for conveyor lines, frames, machine guards, and automated packaging applications.

Medical

Machined components for carts, devices, diagnostics, and surgical systems requiring clean finishes and precision.

Electronics

Machined metal or plastic parts for racks, power systems, and structural components in high-end devices.

Industrial

OEM machine components, motor mounts, and enclosure hardware built for durability and accuracy.

Green Technology

Custom parts for renewable energy systems including solar mounts, EV enclosures, and power supports.

HVAC & Fans

CNC-cut impellers, housings, and support parts for industrial ventilation, heating, and cooling units.

Energy

Precision-machined hardware, connectors, and brackets for grid infrastructure and battery systems.

Aerospace

Aluminum brackets, clamps, and mechanical parts for commercial and defense-grade aircraft systems and testing.

Frequently Asked Questions

Find answers to the most common CNC machining questions we get, like tolerances, file formats, and inspection options. We aim to make your quoting and production process simple, accurate, and fast.

What types of files do you accept?

We accept STEP, IGES, DXF, DWG, and PDF files. We can also assist with design revisions.

Can you hold tight tolerances?

Yes, we machine to ±.0005″ or tighter depending on part geometry and material.

What materials can you machine?

We work with aluminum, stainless steel, carbon steel, brass, copper, plastics, and more.

Explore Our Machined Parts

Our CNC machining projects support everything from surgical carts and control panels to complex housings and structural components. Each part is a reflection of our commitment to precision, consistency, and real-world performance.

Start Your CNC Machining Project

Whether you’re sourcing five parts or scaling into production, Dimar Manufacturing Corporation is your precision partner. Upload your specs, and we’ll respond with a fast, accurate quote backed by decades of real-world machining experience.

Corporate Headquarters

10123 Main StreetClarence, NY 14031

Additional Location

4280 Research ParkwayClarence, NY 14031

Additional Location

40 Anderson RdBuffalo, NY 14225